Understanding your Heat Pump Blower Motor Wiring Diagram is crucial for safe operation and maintenance; this manual provides a dependable guide for confident use.

Congratulations on acquiring your new Blower Motor Wiring Diagram! This guide helps you maximize product benefits, detailing percentage calculations and operational insights.

Calculating percentages, like determining 50 is 25% of 200, is fundamental; this manual offers step-by-step solutions and a free online calculator for precision.

This user manual ensures you can confidently navigate wiring diagrams, understand voltage, amperage, and troubleshoot issues, ensuring optimal performance and safety.

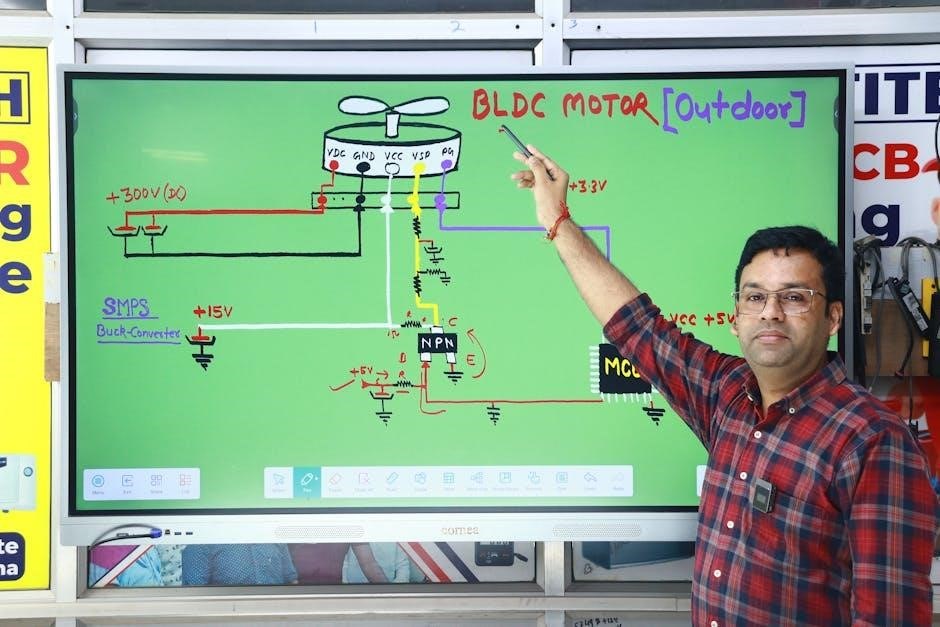

What is a Blower Motor?

A blower motor, central to HVAC systems, is an electrically powered device designed to circulate air. It’s a vital component in furnaces, air conditioners, and heat pumps, responsible for distributing conditioned air throughout a building. Understanding its function is key when referencing a blower motor wiring diagram manual.

These motors come in various types, including PSC (Permanent Split Capacitor) and ECM (Electronically Commutated Motor), each with unique wiring requirements detailed within the manual. The motor’s operation relies on converting electrical energy into mechanical energy, spinning a fan to move air.

Proper functionality ensures efficient heating and cooling. The manual emphasizes the importance of correctly identifying the motor type and its associated wiring configuration. Troubleshooting often begins with verifying the motor’s operation, guided by the wiring diagram for accurate diagnosis and repair.

Essentially, the blower motor is the engine that drives airflow, making it a critical element in maintaining comfortable indoor environments, and the manual is your guide.

Importance of Wiring Diagrams

Blower motor wiring diagrams are indispensable for anyone working with HVAC systems. This manual highlights their critical role in safe and effective installation, maintenance, and repair. A diagram provides a visual representation of the electrical connections, ensuring correct wiring and preventing potentially hazardous situations.

Without a diagram, troubleshooting becomes significantly more difficult and prone to error. The manual stresses the importance of referencing the correct diagram for your specific motor and system configuration. Understanding symbols, color codes, and voltage/amperage ratings is paramount.

Accurate wiring is essential for optimal performance and longevity of the blower motor. The manual serves as a reliable resource, guiding users through complex wiring scenarios. It empowers both professionals and DIY enthusiasts to confidently tackle electrical work.

Ultimately, a wiring diagram is your roadmap to a functioning and safe HVAC system, and this manual is your key to interpreting it.

Safety Precautions

Before commencing any work with blower motor wiring, this manual emphasizes the utmost importance of electrical safety. Always disconnect power at the breaker box or fuse panel to prevent electric shock. Verify the power is off with a reliable voltage tester before touching any wires.

Never work with wet hands or in damp environments. Wear appropriate personal protective equipment (PPE), including insulated gloves and safety glasses. This manual cautions against assuming wires are de-energized; always test first.

If you are unfamiliar with electrical work, consult a qualified HVAC technician. Improper wiring can lead to fire hazards or damage to the equipment. This manual is a guide, not a substitute for professional expertise.

Follow all local electrical codes and regulations. Prioritize safety above all else when working with electrical components.

Understanding Blower Motor Components

This manual details key components – PSC, ECM motors, capacitors, relays, and resistors – essential for interpreting blower motor wiring diagrams and effective troubleshooting.

Understanding these parts, their functions, and interactions is vital for safe and accurate diagnosis and repair of your heating and cooling systems.

Proper identification of each component allows for informed decisions when referencing wiring diagrams and performing maintenance, ensuring optimal system performance.

Blower Motor Types (PSC, ECM)

Permanent Split Capacitor (PSC) motors are a traditional, cost-effective option commonly found in older HVAC systems. These motors utilize a capacitor for starting and running, offering consistent speed but limited efficiency. Wiring diagrams for PSC motors typically show simpler configurations due to their fixed-speed nature.

Electronically Commutated Motors (ECM), conversely, represent a modern advancement in blower motor technology. ECMs utilize an electronic control system to vary speed, resulting in significantly improved energy efficiency and quieter operation.

ECM wiring diagrams are often more complex, reflecting the electronic control module and variable speed capabilities. Understanding the differences between PSC and ECM motors is crucial when interpreting wiring diagrams and performing repairs, as the troubleshooting approaches and component interactions differ substantially. This manual will help you identify each type.

Capacitors and Their Role

Capacitors are essential components in many blower motor systems, particularly those utilizing Permanent Split Capacitor (PSC) motors. Their primary role is to provide the necessary electrical “kick” to start the motor and to maintain a phase shift for continuous running. Without a functioning capacitor, a PSC motor will often fail to start or will run inefficiently.

Wiring diagrams clearly illustrate capacitor placement, typically showing connections to the motor windings and power source. Identifying the capacitor’s microfarad (µF) rating and voltage is critical when replacing a faulty unit.

Incorrect capacitor values can damage the motor or prevent proper operation. This manual emphasizes safe capacitor handling, as they can store a dangerous electrical charge even when power is disconnected. Always discharge the capacitor before handling it, and refer to the wiring diagram for correct replacement procedures.

Relays and Contactors

Relays and contactors act as electrically operated switches, controlling the power supply to the blower motor. They are crucial for safety and functionality, allowing the system to be turned on and off remotely, often by a thermostat. Wiring diagrams depict these components as sets of coils and contacts.

Contactors, typically used for higher amperage motors, handle the main power feed, while relays manage lower-current control circuits. Understanding their operation is vital for troubleshooting power issues.

This manual stresses the importance of verifying relay/contactor coil voltage matches the control signal. A faulty relay or contactor can prevent the motor from running or cause intermittent operation. Always disconnect power before inspecting or replacing these components, and consult the wiring diagram for correct connections.

Resistors and Their Function

Resistors within a blower motor circuit primarily control the motor’s speed by reducing voltage. Multi-speed motors utilize resistors to offer varying fan speeds – high, medium, and low – based on the resistance level selected. Wiring diagrams illustrate resistor placement in series with the motor windings.

These components dissipate excess energy as heat, so proper ventilation is essential. A failed resistor often results in the motor running at only one speed, typically the highest, or not at all.

This manual emphasizes the importance of matching resistor wattage to the motor’s specifications. Incorrect resistance values can damage the motor or create a fire hazard. Always verify resistance with a multimeter and replace faulty resistors with identical replacements.

Decoding a Blower Motor Wiring Diagram

Mastering diagram symbols, color codes, and voltage/amperage readings is key to understanding blower motor circuits; this manual provides essential decoding skills.

Accurate multi-meter readings are vital for troubleshooting; learn to interpret values for safe and effective repairs, as detailed in this guide.

This manual equips you to confidently navigate complex wiring schematics, ensuring proper diagnosis and efficient system maintenance for optimal performance.

Common Wiring Diagram Symbols

Understanding the language of wiring diagrams begins with recognizing common symbols. A straight line typically represents a conductor, while a broken line signifies a neutral wire. Circles often denote components like capacitors or relays, crucial for blower motor operation.

Symbols for switches – single-pole, double-pole, and three-way – are essential for tracing circuit control. Resistors are often depicted as zig-zag lines, indicating resistance to current flow. Grounding symbols, resembling stacked lines, highlight safety connections.

This manual emphasizes the importance of correctly interpreting these symbols. Familiarity with these visual cues allows for accurate tracing of electrical paths, aiding in troubleshooting and repair. Ignoring these symbols can lead to misdiagnosis and potentially dangerous outcomes. Always refer to the diagram’s legend for clarification, ensuring a comprehensive understanding of the blower motor’s wiring configuration.

Proper symbol recognition is the foundation of effective electrical work, and this guide provides a clear pathway to mastering this vital skill.

Color Coding of Wires

Wire color coding is a standardized system crucial for identifying circuit functions within a blower motor system. Black wires typically indicate hot or live conductors, carrying electrical power. White wires generally represent neutral returns, completing the circuit path.

Green or bare copper wires signify grounding, providing a safe path for fault current. Red wires often denote secondary hot leads, frequently used in multi-speed motor applications. Blue wires can indicate fan controls or common connections.

This manual stresses the importance of verifying wire colors against the specific wiring diagram. Variations can occur based on manufacturer and installation practices. Never assume a wire’s function solely based on color; always test for voltage and continuity; Incorrect wiring can cause malfunctions or safety hazards. Consistent color adherence simplifies troubleshooting and ensures accurate repairs.

Understanding these conventions is paramount for safe and effective blower motor maintenance.

Voltage and Amperage Identification

Accurate voltage and amperage identification are fundamental to safe and effective blower motor repair. Wiring diagrams clearly indicate the required voltage – commonly 120V or 240V for residential systems. Using the incorrect voltage can instantly damage the motor or create a fire hazard.

Amperage, measured in amps, indicates the current draw of the motor. This value is crucial for selecting appropriately sized fuses or circuit breakers. Overcurrent protection prevents overheating and potential electrical fires.

This manual emphasizes using a multimeter to verify voltage and amperage before commencing any work. Always disconnect power before testing. Refer to the motor’s nameplate for specified voltage and amperage ratings. Discrepancies indicate a potential problem requiring further investigation. Prioritize safety and accurate measurements.

Proper identification safeguards both the equipment and personnel.

Reading Multi-Meter Values

A multimeter is an indispensable tool for diagnosing blower motor issues. When measuring voltage, ensure the meter is set to the appropriate AC or DC voltage range. A reading close to the diagram’s specification confirms proper power delivery.

For amperage, switch the meter to the amperage setting and connect it in series with the motor’s circuit. Observe the current draw; significant deviations from the nameplate rating suggest a motor fault or obstruction.

Resistance measurements, taken with the power off, can identify open windings or short circuits. Consult the manual for expected resistance values. Accurate readings require proper probe placement and understanding of meter settings.

Always double-check meter settings and connections before taking measurements. Prioritize safety and consult a qualified technician if unsure.

Wiring Diagrams for Different Systems

Diverse systems—furnaces, heat pumps, air conditioners, and whole-house fans—require unique wiring configurations; this manual details each, ensuring correct installation and troubleshooting.

Understanding these variations is vital for safe and efficient operation, referencing specific diagrams for each system type to avoid electrical hazards.

Proper wiring guarantees optimal performance and longevity, aligning with manufacturer specifications and electrical code requirements for each distinct application.

Furnace Blower Motor Wiring

Furnace blower motor wiring typically involves several key components, including the motor itself, a capacitor for starting and running, and various switches for speed control and safety. A common configuration utilizes a 120V or 240V power supply, depending on the motor’s specifications.

Wiring diagrams for furnaces often showcase a multi-speed motor setup, achieved through a combination of series and parallel connections of motor windings. These connections are controlled by relays or a multi-tap switch, allowing for adjustments based on heating demands.

Crucially, the capacitor plays a vital role in providing the necessary phase shift for motor starting and ensuring efficient operation. Incorrect capacitor values can lead to motor failure or reduced airflow. Always consult the furnace’s wiring diagram and the motor’s nameplate for precise specifications. Proper grounding is essential for safety, and adherence to local electrical codes is paramount during installation and repair.

This manual emphasizes the importance of disconnecting power before working on any electrical components and verifying all connections before restoring power.

Heat Pump Blower Motor Wiring

Heat pump blower motor wiring differs from furnace wiring due to the reversing valve and the need to switch between heating and cooling modes. Typically, a heat pump system utilizes a 24V control circuit alongside the 240V power supply for the blower motor.

Wiring diagrams will illustrate connections for the reversing valve solenoid, which directs refrigerant flow, and the outdoor unit control board. The blower motor often operates at multiple speeds, controlled by the thermostat and the heat pump’s control board.

Capacitors are essential for both starting and running the motor, and their correct value is critical for optimal performance. Careful attention must be paid to the wiring of the auxiliary heat strips, which are activated during colder temperatures. This manual stresses the importance of verifying proper grounding and adherence to electrical safety codes.

Always disconnect power before working on the system and consult the specific wiring diagram for your heat pump model.

Air Conditioner Blower Motor Wiring

Air conditioner blower motor wiring is generally simpler than heat pump wiring, as it lacks the reversing valve component. However, understanding the control circuit and power supply is still crucial for safe and effective troubleshooting.

Typically, a 24V thermostat signal activates a contactor, which then supplies 240V power to the blower motor. The wiring diagram will clearly show the connections for the compressor contactor and the blower motor contactor.

Capacitors play a vital role in starting and running the blower motor, and their proper function must be verified. Correct wiring ensures the fan operates efficiently, distributing cooled air throughout the building.

This manual emphasizes the importance of checking for proper grounding and adhering to all applicable electrical codes. Always disconnect power before working on the system and consult the specific wiring diagram for your unit.

Whole-House Fan Blower Motor Wiring

Whole-house fan blower motor wiring differs significantly from HVAC systems, often utilizing a single-speed motor controlled by wall switches or a remote. Understanding the wiring is vital for safe operation and troubleshooting;

Typically, these fans operate on 120V or 240V power, and the wiring diagram will illustrate the connections for the motor, switches, and any safety devices like thermal overload protectors.

Capacitors are frequently used for starting the motor, and their condition is critical for reliable performance. Proper grounding is essential to prevent electrical hazards.

This manual stresses the importance of verifying the fan’s shutter mechanism is functioning correctly before energizing the motor. Always disconnect power before any wiring work and consult the specific diagram for your model.

Troubleshooting with Wiring Diagrams

Utilizing wiring diagrams is essential for diagnosing blower motor issues like no power, constant running, slow speeds, or unusual noises; this manual guides you.

Systematically check voltage, amperage, and component functionality using the diagram to pinpoint faults efficiently and safely, ensuring accurate repairs and optimal performance.

Always disconnect power before troubleshooting and refer to the diagram for correct wiring configurations, preventing further damage and ensuring a safe working environment.

No Power to the Blower Motor

When the blower motor receives no power, a systematic approach using the wiring diagram is crucial. First, verify the power source to the furnace or air handler is active, checking breakers and fuses for any interruptions. Next, consult the diagram to trace the wiring from the power source to the blower motor, inspecting for loose connections or damaged wires along the path.

Utilize a multimeter to confirm voltage is present at various points in the circuit, as indicated on the diagram. Check the blower motor capacitor; a failed capacitor can prevent the motor from starting, even with power present. Also, examine the relays and contactors, ensuring they are engaging correctly to supply power to the motor. If these components test good, the issue may lie within the control board or thermostat wiring, requiring further investigation with the diagram as your guide.

Remember safety first – disconnect power before any inspection or repair!

Blower Motor Runs Constantly

A blower motor running continuously often indicates a problem with the control circuit, and the wiring diagram is essential for diagnosis. Begin by checking the thermostat settings; ensure it’s not set to “on” continuously. Next, examine the limit switches, which should interrupt power to the blower if temperature thresholds are exceeded – a faulty switch can cause constant operation.

Using the wiring diagram, trace the wiring from the thermostat to the control board and then to the blower motor relay. Inspect the relay for sticking or malfunction, preventing it from cycling the motor on and off. A faulty control board can also send a constant signal to the blower. Verify capacitor functionality, as a failing capacitor can sometimes cause erratic motor behavior.

Always disconnect power before inspecting electrical components!

Blower Motor Runs Slowly

A slowly operating blower motor frequently points to voltage issues or capacitor problems, and your wiring diagram is key to pinpointing the source. First, verify the incoming voltage to the motor using a multimeter, comparing it to the diagram’s specified voltage. Low voltage can result from loose connections or a failing transformer.

Crucially, inspect the capacitor – a weak or failing capacitor is a common cause of slow motor speed. Refer to the wiring diagram to locate the capacitor and test its capacitance with a capacitor tester. Also, check for obstructions in the blower wheel or ductwork, which can strain the motor.

Examine wiring connections for corrosion or looseness, as these can create resistance and reduce voltage. Remember to disconnect power before any electrical inspection!

Blower Motor is Noisy

Excessive noise from a blower motor often indicates mechanical issues or electrical problems, and your wiring diagram aids in systematic diagnosis. Begin by visually inspecting the blower wheel for debris, imbalances, or damage – obstructions cause rattling or humming. Next, check the motor bearings; a worn bearing typically produces a grinding or squealing sound.

Consult the wiring diagram to locate the motor and capacitor; a failing capacitor can cause humming. Ensure all mounting screws are tight, as loose components vibrate. Also, verify proper airflow – restricted ducts increase motor strain and noise.

Carefully inspect wiring connections for looseness or arcing, which can create buzzing sounds. Always disconnect power before any electrical inspection!

Advanced Wiring Concepts

Mastering multi-speed and variable speed wiring requires detailed diagram comprehension; thermostats and limit switches add complexity, demanding precise connections for optimal control.

This manual guides you through these advanced configurations, ensuring safe and efficient operation of your blower motor system, maximizing performance.

Understanding these concepts unlocks full system potential, allowing customized comfort and energy savings through precise wiring and component integration.

Multi-Speed Blower Motor Wiring

Multi-speed blower motors offer enhanced comfort and efficiency by adjusting airflow based on heating or cooling demands. Wiring these systems involves tapping into different motor windings, each corresponding to a specific speed setting.

The wiring diagram is paramount, illustrating how to connect these windings to a multi-speed switch or the control board. Typically, you’ll find terminals labeled for low, medium, and high speeds, each requiring a dedicated wire run.

Carefully identify the correct terminals based on your motor’s specifications and the desired speed configuration. Incorrect wiring can lead to motor damage or inefficient operation. Capacitors often play a crucial role in multi-speed systems, providing the necessary starting torque for each speed.

Always double-check connections and ensure proper insulation to prevent shorts. This manual provides detailed diagrams and guidance for safe and effective multi-speed blower motor wiring, maximizing your system’s performance and longevity.

Variable Speed Blower Motor Wiring

Variable speed blower motors, often ECM (Electronically Commutated Motors), provide precise airflow control for optimal comfort and energy savings. Wiring these motors differs significantly from traditional multi-speed setups, relying heavily on low-voltage control signals.

Instead of directly switching motor windings, a thermostat or control board sends a 0-10V DC signal to the motor, dictating its speed. The wiring diagram will illustrate these low-voltage connections, alongside the necessary power supply wiring.

Proper grounding is critical for ECM motors to prevent electrical noise and ensure reliable operation. Shielded wiring is often recommended for the control signal to minimize interference. This manual emphasizes the importance of following the manufacturer’s wiring diagram precisely.

Incorrect wiring can damage the motor or compromise its advanced features. Careful attention to polarity and signal connections is essential for a successful installation and optimal performance.

Wiring with Thermostats

Thermostats act as the central control for blower motors, dictating when they operate and at what speed. Wiring a blower motor to a thermostat requires careful attention to the thermostat’s wiring diagram and the blower motor’s specifications.

Traditional thermostats utilize simple on/off control, while modern smart thermostats offer variable speed control via low-voltage signals. Understanding the thermostat’s terminal designations (R, C, W, G, Y) is crucial for correct wiring.

The “G” terminal typically controls the blower motor, activating it when the thermostat calls for cooling or heating. This manual stresses the importance of verifying compatibility between the thermostat and the blower motor.

Incorrect wiring can lead to the motor not functioning, running constantly, or experiencing damage. Always consult both the thermostat and blower motor wiring diagrams before making any connections.

Wiring with Limit Switches

Limit switches are critical safety devices integrated into blower motor systems, preventing overheating and potential fire hazards. They automatically shut off the blower motor if specific temperature thresholds are exceeded;

Wiring a limit switch involves interrupting the power supply to the blower motor, typically in series with the motor’s power switch or relay. This manual emphasizes the importance of understanding normally open (NO) and normally closed (NC) switch configurations.

Proper installation ensures the switch interrupts power when the limit is reached, safeguarding the system. Incorrect wiring can render the switch ineffective, defeating its safety purpose.

Always consult the blower motor and limit switch wiring diagrams for accurate connections. Testing the switch’s functionality after installation is crucial to verify its operational status and ensure system safety.

Resources and Further Information

Explore online databases and manufacturer-specific diagrams for detailed wiring schematics. Remember electrical code considerations and gather essential tools for safe, effective repairs.

Utilize free online calculators for percentage calculations, aiding in understanding system specifications. This manual encourages continuous learning and safe practices.

Access comprehensive guides and step-by-step instructions to enhance your knowledge of blower motor wiring. Prioritize safety and consult professionals when needed.

Online Wiring Diagram Databases

Numerous online resources offer extensive collections of blower motor wiring diagrams, proving invaluable for troubleshooting and repair. These databases often categorize diagrams by manufacturer, model number, and system type – furnace, heat pump, or air conditioner – streamlining the search process.

Websites dedicated to HVAC (Heating, Ventilation, and Air Conditioning) professionals frequently host user-submitted diagrams and technical documentation. However, always verify the accuracy of information sourced from these platforms, cross-referencing with official manufacturer resources whenever possible.

Subscription-based services provide access to premium wiring diagram libraries, often including detailed schematics and interactive troubleshooting guides. These can be particularly useful for complex systems or older models where documentation is scarce. Remember to prioritize safety and consult a qualified technician if you are unsure about any aspect of the wiring process.

Always double-check the diagram matches your specific blower motor model before commencing any work, as even slight variations can lead to incorrect wiring and potential hazards.

Manufacturer Specific Diagrams

Accessing wiring diagrams directly from the blower motor manufacturer is the most reliable method for ensuring accuracy. Most manufacturers maintain comprehensive online portals or technical support sections on their websites, offering downloadable diagrams in PDF format.

These diagrams are specifically tailored to their products, accounting for unique wiring configurations and component specifications. Utilizing manufacturer-provided resources minimizes the risk of errors and ensures compatibility with replacement parts.

Often, you’ll need the blower motor’s model number and serial number to locate the correct diagram. Some manufacturers require registration or a service account to access their technical documentation.

Contacting the manufacturer’s customer support directly can also be beneficial, especially for older or less common models where online resources are limited. Prioritize these official sources for safe and effective repairs.

Electrical Code Considerations

All blower motor wiring must adhere to local and national electrical codes, such as the National Electrical Code (NEC) in the United States. These codes dictate safe wiring practices, grounding requirements, and appropriate wire gauge for the amperage load.

Proper grounding is critical to prevent electrical shock and ensure the safe operation of the blower motor. Wiring diagrams should clearly indicate grounding points and procedures. Always disconnect power before working on electrical systems.

Compliance with code ensures the longevity and reliability of the installation, minimizing the risk of fire hazards or equipment malfunction. Permits may be required for certain wiring modifications or installations.

Consult a qualified electrician if you are unfamiliar with electrical codes or lack the necessary expertise to perform wiring safely and correctly. Ignoring code requirements can void warranties and create dangerous conditions;

Tools Needed for Wiring Repair

Essential tools for blower motor wiring repair include a multimeter for voltage and continuity testing, wire strippers for preparing wires, and pliers for bending and securing connections. A screwdriver set, encompassing various head types, is also crucial.

Safety equipment, such as insulated gloves and safety glasses, is paramount when working with electricity. A wire connector tool simplifies joining wires, while electrical tape provides insulation and protection.

For more complex repairs, a voltage tester confirms power is off, and a circuit tracer aids in identifying wire paths. Having a dedicated wiring diagram manual readily available is invaluable.

Proper tool selection ensures efficient and safe repairs. Investing in quality tools enhances accuracy and minimizes the risk of damaging components or causing electrical hazards. Always prioritize safety when working with electrical systems.