Porter-Cable Air Compressor Manual 150 PSI: A Comprehensive Guide

This comprehensive guide details operation‚ maintenance‚ and troubleshooting for Porter-Cable 150 PSI air compressors‚ ensuring optimal performance and longevity․

Factory service centers and PDF manuals are readily available‚ alongside disassembly guides for qualified technicians․

Disassembly beyond the manual’s scope isn’t advised‚ prioritizing safe and effective compressor utilization for all users․

Understanding Your Porter-Cable Air Compressor

Porter-Cable air compressors‚ particularly those rated at 150 PSI‚ are versatile tools designed for a wide array of pneumatic applications․ Understanding the core functionalities and limitations of your specific model is paramount for safe and efficient operation․ These compressors utilize an electric motor to power an air pump‚ compressing atmospheric air into a storage tank․

The pressurized air is then delivered through an air hose to power various tools‚ such as nail guns‚ impact wrenches‚ and spray guns․ Key considerations include the tank capacity‚ measured in gallons‚ which dictates the amount of stored air available for use․ The compressor’s horsepower (HP) determines its pumping speed and ability to maintain pressure during continuous operation․

Furthermore‚ recognizing the importance of adhering to the manual’s guidelines regarding proper usage and maintenance will significantly extend the lifespan of your Porter-Cable compressor and ensure consistent performance․ Disassembly should only be undertaken by qualified personnel․

Safety Precautions and Warnings

Operating a Porter-Cable air compressor requires strict adherence to safety guidelines to prevent injury and damage․ Always disconnect the power supply before performing any maintenance or repairs․ Never exceed the maximum pressure rating of 150 PSI‚ as this could lead to tank rupture․ Wear appropriate eye and ear protection during operation‚ as compressors can be loud and debris may be expelled․

Ensure the compressor is placed on a stable‚ level surface to prevent tipping․ Avoid operating the compressor in wet or flammable environments․ Regularly inspect the air hose for cracks or damage‚ and never use a damaged hose․ Disassembly or modification beyond the scope of the manual voids the warranty and may compromise safety․

Never attempt to repair the compressor yourself if you are not a qualified technician․ Refer to the manual for detailed safety instructions and warnings specific to your model․

Key Components and Their Functions

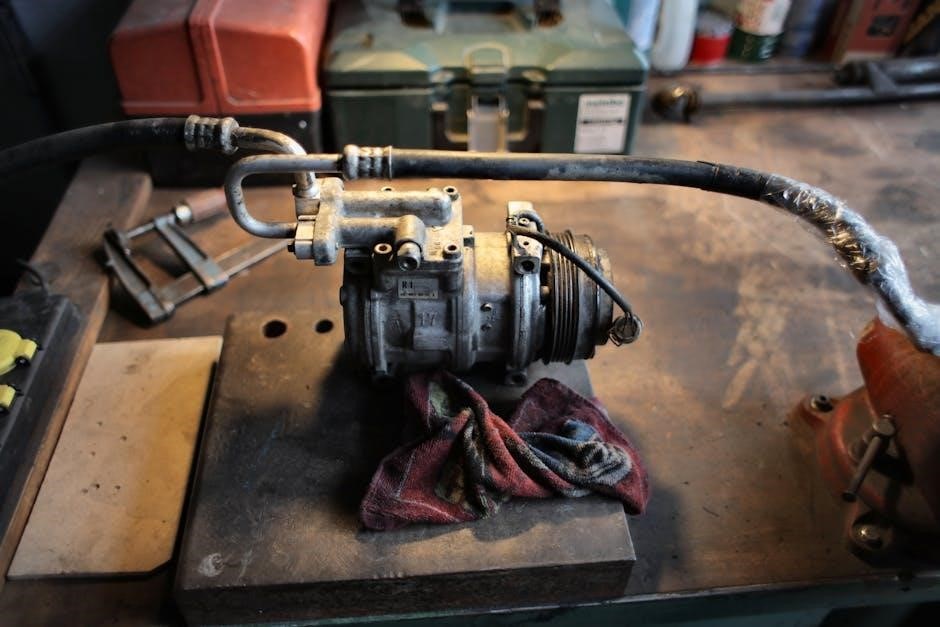

Porter-Cable 150 PSI air compressors comprise several key components working in unison․ The air tank stores compressed air‚ while the motor drives the pump‚ which pressurizes the tank․ A pressure switch automatically starts and stops the motor to maintain the desired pressure․ The regulator controls the output pressure delivered to tools‚ and the safety valve prevents over-pressurization․

The air filter removes contaminants from the intake air‚ protecting the pump․ Hoses and fittings deliver air to tools‚ and the power cord supplies electricity․ Understanding each component’s function is crucial for proper operation and maintenance․ Refer to the manual for detailed diagrams and explanations specific to your model․

Operation and Setup

Proper setup and operation involve initial inspection‚ connecting to an air source‚ adjusting pressure‚ and following safe power-on/off procedures․

Always consult the manual for model-specific instructions to ensure optimal performance and prevent damage to the compressor․

Initial Setup and Inspection

Before first use‚ carefully unpack your Porter-Cable 150 PSI air compressor and inspect it for any shipping damage․ Verify all components are present‚ referencing the parts list in your owner’s manual․ Check the oil level through the sight glass; if low‚ add the recommended oil type as specified in the manual – typically a non-detergent air compressor oil․

Ensure the air tank is free of moisture and debris․ Inspect all air hoses‚ fittings‚ and connections for tightness and damage․ Confirm the pressure switch and safety valve are functioning correctly․ A visual inspection of the power cord is crucial‚ looking for cuts or fraying․ Proper grounding is essential for safety; verify the compressor is connected to a grounded outlet․

Familiarize yourself with the location of all controls‚ including the power switch‚ regulator‚ and drain valve․ Read the entire manual before operating the compressor to understand its features and safety precautions․

Connecting to an Air Source

Connecting to an air source involves selecting the appropriate air hose and fittings compatible with your Porter-Cable 150 PSI compressor’s quick-connect coupler․ Ensure the hose is rated for at least the compressor’s maximum pressure (150 PSI) and is in good condition‚ free from cracks or abrasions․ Securely attach the hose to the compressor’s outlet‚ ensuring a tight‚ leak-free connection․

For stationary setups‚ consider using a fixed air line with a regulator and filter to provide clean‚ consistent air pressure․ Always use a moisture trap or inline filter to prevent water and debris from entering your air tools‚ extending their lifespan․ Never exceed the maximum pressure rating of your air tools․

Before operation‚ double-check all connections for leaks using a soapy water solution․ Tighten fittings as needed to eliminate any air escaping․

Adjusting Pressure and Airflow

Adjusting pressure and airflow on your Porter-Cable 150 PSI compressor is crucial for optimal tool performance․ Locate the regulator knob on the compressor and rotate it clockwise to increase pressure and counterclockwise to decrease it․ Monitor the pressure gauge to set the desired PSI for your specific air tool․

Airflow is indirectly controlled by the compressor’s output and the tool’s air consumption (CFM)․ Ensure the compressor’s CFM rating meets or exceeds the tool’s requirements․ Using a regulator helps maintain consistent pressure‚ even with fluctuating airflow demands;

Always start with a lower pressure and gradually increase it until the tool operates effectively․ Avoid exceeding the tool’s maximum pressure rating to prevent damage or injury․

Powering On and Off Procedures

Powering on your Porter-Cable 150 PSI compressor requires a grounded electrical outlet matching the compressor’s voltage․ Ensure the pressure regulator is set to the desired PSI before switching on․ Press the power switch to ‘ON’ – the compressor will begin filling the tank․ Allow sufficient time for the tank to reach the set pressure before using any air tools․

To power off‚ first disconnect any air tools․ Switch the power button to ‘OFF’․ Always unplug the compressor from the electrical outlet when not in use or during maintenance․ This prevents accidental starting and ensures safety․

Never attempt to open the pressure relief valve while the compressor is running․ Proper on/off procedures extend the compressor’s lifespan and guarantee safe operation․

Maintenance and Troubleshooting

Regular maintenance—daily checks‚ weekly procedures‚ and oil changes—ensures peak performance․ Troubleshooting common issues like low pressure or leaks is crucial for longevity․

Daily Maintenance Checklist

Before each use‚ thoroughly inspect the Porter-Cable air compressor for any visible damage‚ including loose parts‚ frayed wires‚ or cracks in the tank․ Drain the tank completely to prevent corrosion and ensure accurate pressure readings; this is a critical step for safety and performance․

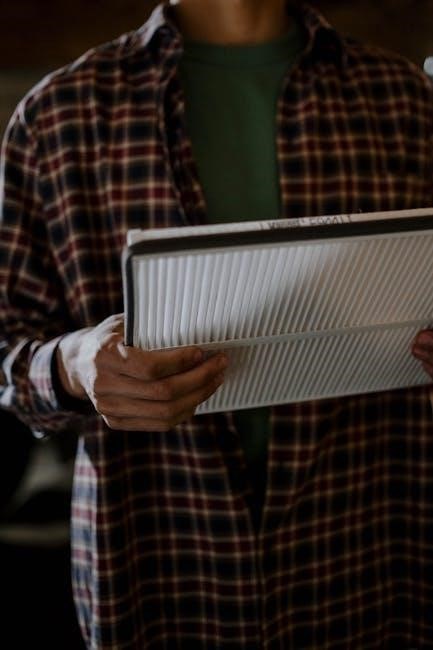

Check the oil level through the sight glass‚ adding oil if necessary to maintain the proper level – refer to your specific model’s manual for the correct type and amount․ Examine the air filter for dirt and debris‚ cleaning or replacing it as needed to ensure optimal airflow․

Verify all connections are tight and secure‚ listening for any air leaks․ Ensure the compressor is placed on a stable‚ level surface‚ free from obstructions․ A quick visual inspection and these simple steps will contribute significantly to the longevity and reliable operation of your Porter-Cable unit․

Weekly Maintenance Procedures

Expand upon daily checks with a more detailed inspection of the Porter-Cable air compressor․ Thoroughly clean the exterior surfaces‚ removing any dust or debris that may accumulate․ Inspect the safety valve to ensure it’s functioning correctly‚ releasing pressure if the compressor exceeds its maximum limit․

Check the drive belt for wear and tear‚ adjusting tension if necessary․ Examine the air hose for cuts‚ abrasions‚ or leaks‚ replacing it if damaged․ Wipe down the oil fill cap and dipstick‚ ensuring they are clean and properly sealed․

Listen for unusual noises during operation‚ which could indicate a potential problem․ Consistent weekly maintenance will help prevent costly repairs and extend the life of your Porter-Cable compressor‚ maintaining optimal performance․

Oil Change and Filter Replacement

Regular oil changes are crucial for Porter-Cable air compressor longevity․ Consult your specific model’s manual for the recommended oil type and change interval․ Typically‚ this is every 200-300 hours of operation․ Drain the old oil while the compressor is warm‚ but not hot‚ and dispose of it responsibly․

Replace the air filter concurrently with the oil change․ A clean filter ensures optimal airflow and prevents contaminants from entering the compressor․ Inspect the filter housing for any damage or debris․

Proper oil and filter maintenance significantly reduces wear and tear‚ improving performance and extending the lifespan of your Porter-Cable compressor․ Always refer to the manual for detailed instructions specific to your model․

Troubleshooting Common Issues (Low Pressure‚ Leaks)

Low pressure often indicates a dirty air filter‚ insufficient oil‚ or a regulator malfunction․ Check and replace the filter‚ verify oil levels‚ and inspect the regulator for proper adjustment․ Air leaks can occur at fittings‚ hoses‚ or the tank․ Tighten connections and inspect hoses for cracks or damage․

Listen for hissing sounds to pinpoint leak locations․ If the tank itself is leaking‚ discontinue use immediately and consult a qualified technician․ Refer to your Porter-Cable manual for specific troubleshooting steps related to your model․

Regular maintenance prevents many issues․ If problems persist‚ contact Porter-Cable factory service centers for professional assistance and genuine replacement parts․

Specific Models and Variations (150 PSI Range)

Porter-Cable offers diverse 150 PSI air compressors‚ including the C2002 and C2002-WK‚ each with unique features and capabilities for varied applications․

Porter-Cable C2002 Air Compressor Details

The Porter-Cable C2002 is a popular 6-gallon‚ 150 PSI pancake air compressor known for its portability and versatility․ This model features a powerful 1․5 HP motor delivering 2․6 CFM @ 90 PSI‚ suitable for various pneumatic tools like nailers‚ staplers‚ and inflation devices․

Its lightweight design and compact size make it easy to transport to different job sites․ The C2002 boasts a high-flow regulator and couplers‚ ensuring consistent air pressure․ Durable construction and an oil-free pump contribute to reduced maintenance․

Users appreciate its quick recovery time and relatively quiet operation․ However‚ the 6-gallon tank capacity may require more frequent refills for continuous‚ high-air-demand applications․ Proper maintenance‚ as outlined in the manual‚ is crucial for optimal performance and longevity․

Porter-Cable C2002-WK Air Compressor Features

The Porter-Cable C2002-WK is a kit version of the C2002‚ including 13 versatile pneumatic accessories‚ enhancing its value and usability․ This 6-gallon‚ 150 PSI pancake air compressor retains the core features of the base model – a 1․5 HP motor and 2․6 CFM @ 90 PSI output․

The “WK” kit adds a blow gun‚ tire inflator‚ spray gun‚ and various quick-connect adapters‚ making it ideal for DIY enthusiasts and professionals alike․ Its portability remains a key benefit‚ alongside the oil-free pump for low maintenance․

The included accessories expand the compressor’s application range‚ from inflating tires to detailed spray painting․ Refer to the manual for safe operation and accessory compatibility․ Regular maintenance ensures peak performance of both the compressor and its included tools․

Comparing Different 150 PSI Porter-Cable Models

Porter-Cable offers several 150 PSI air compressors‚ each catering to different needs․ The C2002‚ a popular 6-gallon pancake model‚ prioritizes portability and convenience․ The C2002-WK adds a valuable accessory kit‚ enhancing versatility for various tasks․

Larger tank models‚ like some variations within the PXCM1 series‚ provide extended runtime for tools demanding consistent airflow․ CFM (Cubic Feet per Minute) ratings are crucial; higher CFM supports more powerful tools․ Oil-free pumps‚ common across many models‚ reduce maintenance but may have a shorter lifespan than oil-lubricated versions․

Consult the manual for each model’s specific specifications and recommended applications․ Consider tank size‚ CFM output‚ and accessory needs when choosing the best Porter-Cable compressor for your projects․

Advanced Features and Techniques

Optimizing airflow with regulators and filters enhances tool performance‚ while understanding CFM ensures compatibility with various pneumatic tools for efficient operation․

Using Regulators and Filters

Air regulators are crucial components for maintaining consistent pressure‚ preventing damage to tools and ensuring optimal performance․ Porter-Cable compressors often feature adjustable regulators allowing users to tailor the output to specific tool requirements․ Incorrect pressure can lead to inefficient operation or even tool failure‚ highlighting the regulator’s importance․

Air filters are equally vital‚ removing moisture and debris from the compressed air stream․ Contaminants can cause internal corrosion‚ reduce tool lifespan‚ and compromise work quality․ Regularly inspect and replace filters as recommended in the manual to maintain clean‚ dry air․

Combining a regulator and filter – often found as a combined unit – provides comprehensive air quality control․ Proper use extends tool life‚ improves efficiency‚ and guarantees professional-grade results with your Porter-Cable compressor․

Optimizing Airflow for Specific Tools

Porter-Cable air compressors deliver 150 PSI‚ but achieving optimal performance requires matching airflow (CFM) to tool demands․ Tools like impact wrenches and sanders necessitate higher CFM than smaller nailers or airbrushes․ Consult your tool’s manual to determine its CFM requirement․

Insufficient CFM results in reduced power and intermittent operation․ Conversely‚ excessive CFM doesn’t enhance performance but can strain the compressor․ Utilize the compressor’s regulator to fine-tune airflow‚ balancing power with efficiency․

Understanding your Porter-Cable compressor’s CFM output at various PSI levels is key․ Proper airflow optimization maximizes tool effectiveness‚ extends compressor life‚ and ensures consistent‚ high-quality results for every application․

Understanding CFM (Cubic Feet per Minute)

CFM‚ or Cubic Feet per Minute‚ is the critical measurement of an air compressor’s delivery capacity․ It dictates the volume of air supplied to power pneumatic tools․ A Porter-Cable 150 PSI compressor’s CFM rating indicates how much air it can consistently provide at that pressure․

Higher CFM ratings are essential for tools demanding substantial airflow‚ like spray guns and grinders․ Lower CFM suffices for smaller tools such as nailers and staplers․ Mismatched CFM leads to inefficient operation – insufficient CFM causes power loss‚ while excessive CFM is wasteful․

Always verify your tool’s CFM requirement before operation․ Refer to your Porter-Cable compressor’s manual for its CFM output at various PSI settings to ensure compatibility and optimal performance․

Repair and Parts Replacement

Genuine Porter-Cable replacement parts ensure compatibility and performance․ Factory service centers offer professional repairs‚ while manuals guide qualified users through disassembly and reassembly․

Finding Replacement Parts

Locating replacement parts for your Porter-Cable 150 PSI air compressor is crucial for maintaining its functionality and extending its lifespan․ Several avenues are available to ensure you obtain the correct components․ Firstly‚ the Porter-Cable website itself often features a parts diagram and online ordering system‚ allowing you to identify and purchase parts directly․

Alternatively‚ numerous online retailers specializing in power tool parts carry a wide selection of Porter-Cable components․ These include authorized dealers and independent suppliers․ When ordering online‚ always verify the part number against your compressor’s manual to guarantee compatibility․ Local hardware stores and tool repair shops may also stock common replacement parts‚ such as filters‚ belts‚ and check valves․

For more specialized or discontinued parts‚ contacting a Porter-Cable factory service center is recommended․ They can often source parts that are not readily available elsewhere․ Remember to have your compressor’s model number and serial number handy when searching for parts‚ as this will help ensure you receive the correct replacements․

Disassembly and Reassembly Guides

Disassembling your Porter-Cable 150 PSI air compressor should only be undertaken by individuals with mechanical aptitude and a thorough understanding of compressor components․ The official Porter-Cable manual provides limited disassembly instructions‚ primarily focused on basic maintenance tasks․ More extensive disassembly requires caution and detailed documentation․

Before beginning‚ disconnect the power supply and relieve all air pressure․ Carefully label and organize all parts as you remove them‚ taking photographs to aid reassembly․ Online resources‚ including video tutorials and forum discussions‚ can supplement the manual‚ offering step-by-step guidance for specific repairs․

Reassembly involves reversing the disassembly process‚ ensuring all components are correctly aligned and securely fastened․ Pay close attention to torque specifications for bolts and screws․ If you encounter difficulties or are unsure about any step‚ consult a qualified technician or a Porter-Cable factory service center․

Porter-Cable Factory Service Centers

Porter-Cable provides a network of authorized factory service centers for repairs and maintenance beyond the scope of the user manual․ These centers employ trained technicians with specialized knowledge of Porter-Cable air compressors‚ ensuring quality service and genuine parts replacement․

Locating a service center is typically done through the Porter-Cable website‚ utilizing a zip code search tool․ Contacting Porter-Cable customer support directly can also provide the nearest authorized service location․ Before visiting‚ it’s advisable to obtain a repair estimate and inquire about turnaround times․

Utilizing a factory service center guarantees repairs are performed to Porter-Cable’s standards‚ maintaining the compressor’s warranty and optimal performance․ Attempting complex repairs without proper training can void the warranty and potentially damage the unit;

Manual Resources and Downloads

Official Porter-Cable manuals in PDF format are readily available online‚ alongside support forums and communities for assistance with your air compressor․

Official Porter-Cable Manuals (PDF)

Porter-Cable provides readily accessible PDF versions of their air compressor manuals directly on their official website․ These digital resources offer detailed instructions covering all aspects of your 150 PSI model‚ from initial setup and safe operation to comprehensive maintenance schedules and troubleshooting guides․

Downloading the manual allows for convenient offline access‚ ensuring you always have critical information at your fingertips‚ even without an internet connection․ The PDF format ensures compatibility across various devices‚ including computers‚ tablets‚ and smartphones․

These manuals typically include exploded diagrams illustrating key components‚ aiding in parts identification and potential repairs․ Always refer to the official Porter-Cable manual specific to your model number for the most accurate and up-to-date information‚ guaranteeing safe and effective operation of your air compressor․

Online Support Forums and Communities

Numerous online platforms offer valuable support for Porter-Cable 150 PSI air compressor owners․ Dedicated forums and communities provide a space to connect with fellow users‚ share experiences‚ and seek advice on troubleshooting common issues or performing maintenance․

These online resources often feature detailed discussions‚ user-submitted tips‚ and even video tutorials demonstrating repair procedures․ Searching these forums can quickly yield solutions to specific problems you may encounter with your air compressor․

Remember to always verify information obtained from online sources with the official Porter-Cable manual and exercise caution when attempting repairs․ Active participation in these communities can significantly enhance your understanding and prolong the life of your tool․

Warranty Information and Claims

Porter-Cable offers a warranty on its 150 PSI air compressors‚ protecting against manufacturing defects and component failures․ The specific terms and duration of the warranty vary depending on the model and date of purchase‚ so carefully review the documentation included with your compressor․

Typically‚ the warranty covers defects in materials and workmanship for a defined period‚ often one to three years․ To initiate a warranty claim‚ you’ll generally need to provide proof of purchase and a detailed description of the issue․

Contact Porter-Cable’s customer service department or visit their official website for claim submission instructions and authorized service center locations․ Retain your manual and purchase receipt for streamlined processing․